The core function of an industrial granulator machine is to convert larger plastic parts or scrap into uniform granules. Unlike a simple shredder, a granulator uses precise shearing with a rotor and stationary knives to produce clean, even granules that are suitable for re-processing. For example, The Mark-Costello Co. notes that “granulators rely on a shearing action created by precisely machined rotating and stationary knives” to deliver consistent size and clean edges. Key design features to look for

Heavy-duty rotor assembly & high-quality knives: The blades must endure tough, abrasive applications (for example, film, thick molded parts, or off-cuts). Durable construction makes a difference in uptime and maintenance. Feed throat and hopper design: A well-engineered feed system allows consistent material flow and minimises bridging or clogging. Inline feed from a press or conveyor improves efficiency. Screen or granule-size control: A screen or grate under the cutting chamber determines particle size and helps ensure uniform output. Uniform granules improve downstream processing.

Mark Costello has been a trusted name in waste management for decades, delivering reliable and effective solutions that businesses count on.

Using the latest technology, We ensures that waste management systems are efficient and up to industry standards, from food digesters to compactors.

At Mark Costello,we provides tailored waste management solutions that fit each business’s unique needs, ensuring a smooth integration into existing operations.

Mark Costello is dedicated to helping businesses achieve their sustainability goals by turning waste into valuable resources, supporting a greener future.

Send us a message with your questions or concerns and our team member will contact you. We’d love to hear from you.

Dear Mr. Markle,

I have been working in the Plant Operations of Hospitals for the past 20 years. During that time I have had the responsibility of maintaining various autoclaves for the treatment of biohazardous medical waste.

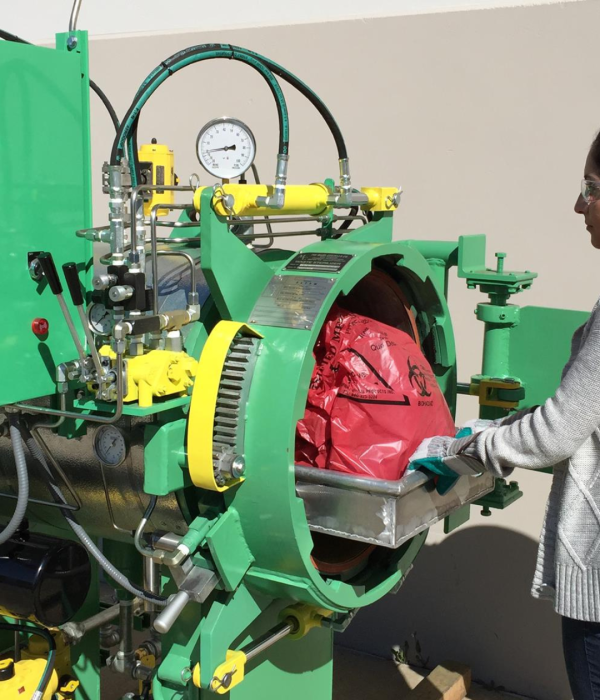

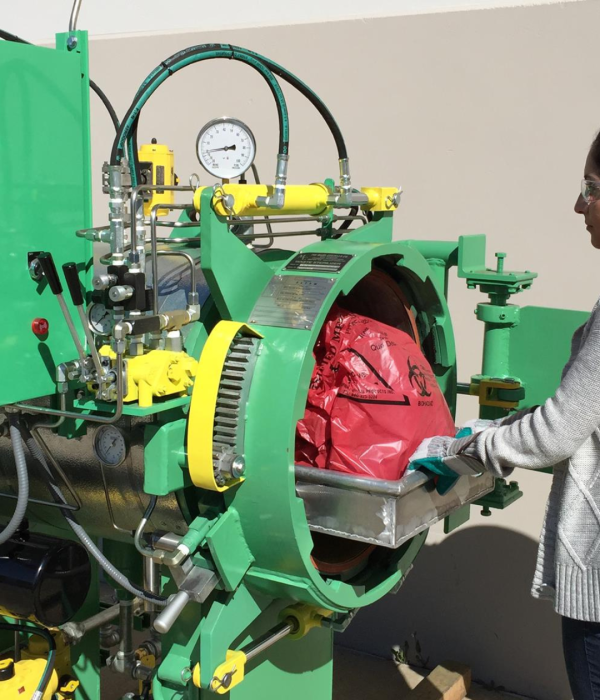

When I came to Doctors Medical Center a year and a half ago I found myself in charge of maintaining a Mark-Costello Co. autoclave that was nearly eight years old. After my past experience of trying to keep a high vacuum system with consistent problems in operation, I find maintaining the Mark-Costello gravity fed autoclave a pleasure, as there is seldom a malfunction. I attribute this to the fact they have kept the design simple with no need for highly technical maintenance and high dollar repair parts.

As a point of information, the Model we operate is a AS 512 equipped with a unique “pull out drawer” making it easy for the Housekeeping Staff to load. This unit has a capacity of approximately 750 lbs. per cycle.

We expect to keep our Mark-Costello autoclave in operation for another 8 years or longer !

Dear Mr. Markle:

San Ramon regional Medical Center has owned and operated a Model AS46 Mark-Costello Medical Waste Sterilizer for the past eight years. We are pleased with performance of this equipment and have had a fine working relationship with the Mark-Costello Company. The system continues to function well and allows our facility to avoid the liability and high cost of packaging and hauling untreated infectious waste.

We Anticipate several more years of operation from this waste treatment system

Saludos,

La presente es para agradecer sus servicios a nuestra compañia. Su equipo de trabajo ha sido muy atento y diligente en las gestiones realizadas. Estamos muy complacidos con el equipo, el precio y la calidad de sus servicios.

Esperamos seguir contando con una excelente relacion de negocios en un futuro muy cercano.

Greetings,

This letter is to thank you for your services to our company. Your teamwork has been very attentive and diligent in the way it has been carried out. We are very pleased with the teamwork, the price and the quality of your services.

We expect to continue an excellent business relationship with you in the near future.

To whom it may concern,

Pleased with the equipment

We are quite pleased with our Mark-Costello sterilizer. The sterilizer has been working fine for many years. We recently purchased additional equipment from them, and are impressed with their response time and friendly service. We hope to continue a great working relationship with Mark-Costello in the future for additional pieces of equipment.

“It’s been a great relationship with The Mark-Costello Company; they are very dependable to all of our waste handling requirements and have made us aware of the importance of recycling and the upcoming waste handling issues in the future.”

“We have been very pleased with the performance and the cost savings that the trash compactors from The Mark-Costello Company have provided to our school district.”

My name is David E. and I am responsible for a Mark Costello Co. Auto-Clave, at an inflight Kitchen out here in Kona Hawaii, that is overseen by the USDA / Custom and Borders, federal inspectors. (as you can imagine that is a challenge in its self).

The products that Mark Costello Co. is producing are of good quality. The auto – clave that I am responsible for works 24/7, with very few break downs. This is the only unit available in Kona, making daily operation is critical.

It is nice to know that when I call for tech support and parts, the courteous staff always responds promptly. Being out here in the middle of the pacific, that is crucial to our operation.

I would highly recommend Mark Costello Co.

Most thermoplastics can be processed using a granulator, including HDPE, LDPE, PP, PET, ABS, and PVC. The specific machine configuration depends on material properties like density, elasticity, and abrasiveness

A shredder is used for coarse size reduction and is ideal for bulky or mixed materials. A grinder may pulverize material more finely. A granulator, on the other hand, produces uniform-sized granules with clean edges that are ready for reprocessing—making it ideal for closed-loop manufacturing systems.

Granulators can be loud, especially high-capacity units. However, our machines are designed with sound-insulated housings and vibration-reduction features. Optional enclosures and silencers are available for noise-sensitive environments.

Absolutely. The Mark-Costello Co. provides integration services including automated feeding, PLC control systems, and remote monitoring. We design systems that work inline with molding, extrusion, or trimming equipment.

Typical output sizes range from 1/8 inch (3mm) to as small as 3/64 inch (1.2mm), depending on the screen used. We’ll help you select the right screen for your application to ensure compatibility with downstream equipment.

Regular blade inspection and sharpening, screen cleaning, and bearing checks are essential. Our machines are built for easy maintenance, and we offer