Choosing Mark-Costello’s Steel Belt Conveyor Systems means more than just acquiring robust equipment—it means partnering with one of the most comprehensive sales and service networks in the industry. Here’s what sets our offering apart:

Industry-Leading Service Network

Mark-Costello backs its steelbelt systems with a deep network of specialized technicians and support staff. From installation and commissioning to preventative maintenance and emergency service, we ensure minimal downtime and ongoing operational reliability.

Expert Consultation & Quoting

Planning a new installation or retrofitting an existing facility? Fill out our quote request form, and a Mark-Costello representative will reach out with tailored recommendations—ensuring your conveyor configuration meets your throughput, space, and processing needs precisely.

Custom Engineering Flexibility

Your facility has unique requirements. Whether you need a specific width, motor rating, chain pitch, or run length, we offer flexible engineering options to match your workflow, layout constraints, and material handling demands.

Pit covers, variable speed drives, or component upgrades can be tailored to fit your operational standards and safety compliance.

Safety & Maintenance Prioritized

Every system incorporates protective pit covers to keep operators safe and reduce contamination. High-quality bearings and drive components reduce wear, simplifying maintenance schedules and extending system lifespan.

We also offer optional training modules to help your team operate and maintain your conveyor efficiently.

Future-Proofing and Upgrades

As waste handling operations evolve—whether due to higher throughput targets, new materials, or process changes—our steelbelt conveyors grow with you. Components like motors, belts, or controls can be easily upgraded to scale capacity without a system overhaul.

Trusted Industry Reputation

With decades of experience supporting waste and materials processing facilities, Mark-Costello has earned trust as a supplier that delivers durable, reliable systems paired with responsive service.

Mark Costello has been a trusted name in waste management for decades, delivering reliable and effective solutions that businesses count on.

Using the latest technology, We ensures that waste management systems are efficient and up to industry standards, from food digesters to compactors.

At Mark Costello,we provides tailored waste management solutions that fit each business’s unique needs, ensuring a smooth integration into existing operations.

Mark Costello is dedicated to helping businesses achieve their sustainability goals by turning waste into valuable resources, supporting a greener future.

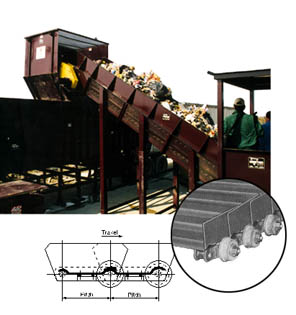

Style A1 Heavy Duty Steel Apron Belt. The shallow double beaded pans are recommended for heavy duty continuous service, high impact loading such as MSW or for handling abrasive materials.

A superior, 3/8″ or 1/2″ pan belt for extreme service up to 8 ft wide. SA conveyors are used for high volume (20 to 50 tons/hour), heavy-duty applications such as feeding MSW into Mark-Costello’s TS-2000 Transfer System compactor, large Two-Ram scrap balers, C&D lines, and mixed waste lines.

Features Include:

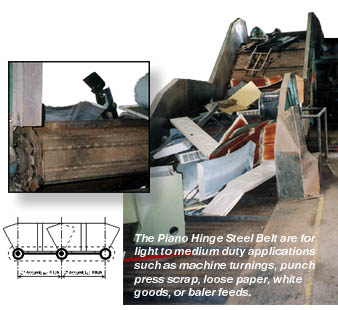

A competitively priced equivalent to other piano hinged belts up to 7 ft. wide. SE conveyors can be used for high volume (12 to 30 tons/hour), heavy-duty applications such as precrusher compactor feeds, large Two-Ram scrap balers, and mixed waste lines.

Features Include:

| Product Class | Application | Width up to: | Shaft Elev. | Pit Length |

| SE | High volume (12 to 30 tph) Variable Speed Control (VS) standard | 7 ft. | up to 18 ft. | up to 100 ft. |

| SA | High volume (20 to 50 tph) Variable Speed Control (VS) standard | 8 ft. | up to 18 ft. | up to 100 ft. |

Send us a message with your questions or concerns and our team member will contact you. We’d love to hear from you.