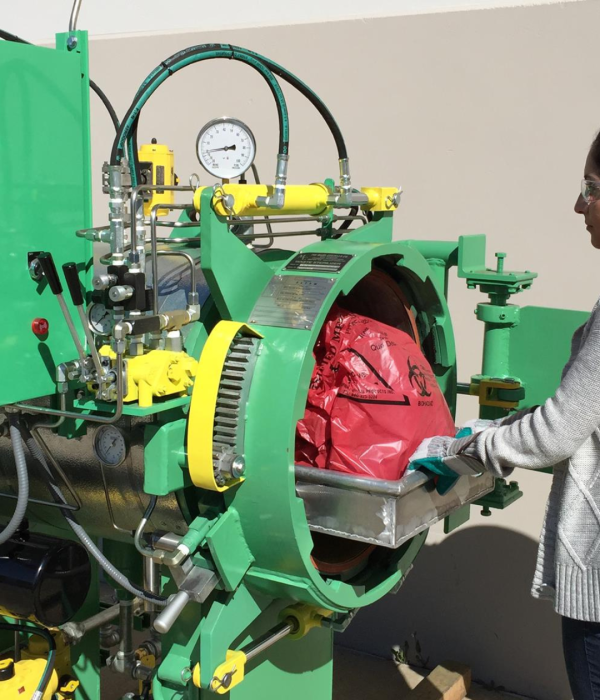

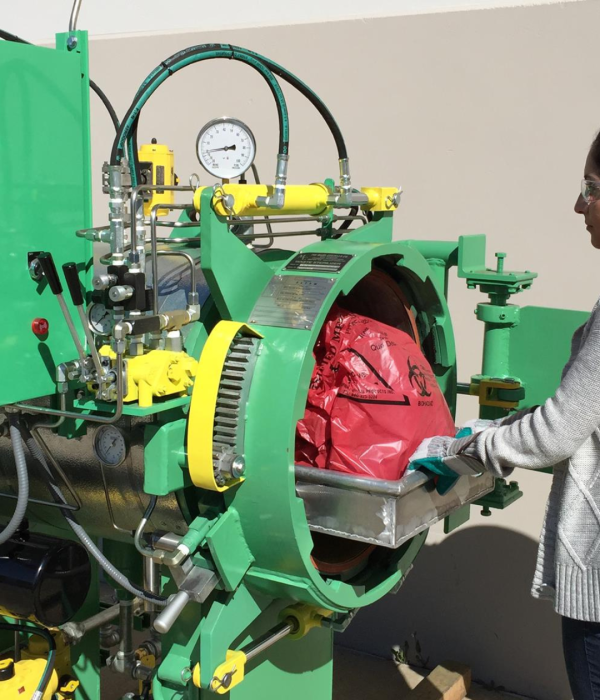

The core function of an industrial granulator machine is to convert larger plastic parts or scrap into uniform granules. Unlike a simple shredder, a granulator uses precise shearing with a rotor and stationary knives to produce clean, even granules that are suitable for re-processing. For example, The Mark-Costello Co. notes that “granulators rely on a shearing action created by precisely machined rotating and stationary knives” to deliver consistent size and clean edges. Key design features to look for

Heavy-duty rotor assembly & high-quality knives: The blades must endure tough, abrasive applications (for example, film, thick molded parts, or off-cuts). Durable construction makes a difference in uptime and maintenance. Feed throat and hopper design: A well-engineered feed system allows consistent material flow and minimises bridging or clogging. Inline feed from a press or conveyor improves efficiency. Screen or granule-size control: A screen or grate under the cutting chamber determines particle size and helps ensure uniform output. Uniform granules improve downstream processing.

Mark Costello has been a trusted name in waste management for decades, delivering reliable and effective solutions that businesses count on.

Using the latest technology, We ensures that waste management systems are efficient and up to industry standards, from food digesters to compactors.

At Mark Costello,we provides tailored waste management solutions that fit each business’s unique needs, ensuring a smooth integration into existing operations.

Mark Costello is dedicated to helping businesses achieve their sustainability goals by turning waste into valuable resources, supporting a greener future.

Send us a message with your questions or concerns and our team member will contact you. We’d love to hear from you.

Most thermoplastics can be processed using a granulator, including HDPE, LDPE, PP, PET, ABS, and PVC. The specific machine configuration depends on material properties like density, elasticity, and abrasiveness

A shredder is used for coarse size reduction and is ideal for bulky or mixed materials. A grinder may pulverize material more finely. A granulator, on the other hand, produces uniform-sized granules with clean edges that are ready for reprocessing—making it ideal for closed-loop manufacturing systems.

Granulators can be loud, especially high-capacity units. However, our machines are designed with sound-insulated housings and vibration-reduction features. Optional enclosures and silencers are available for noise-sensitive environments.

Absolutely. The Mark-Costello Co. provides integration services including automated feeding, PLC control systems, and remote monitoring. We design systems that work inline with molding, extrusion, or trimming equipment.

Typical output sizes range from 1/8 inch (3mm) to as small as 3/64 inch (1.2mm), depending on the screen used. We’ll help you select the right screen for your application to ensure compatibility with downstream equipment.

Regular blade inspection and sharpening, screen cleaning, and bearing checks are essential. Our machines are built for easy maintenance, and we offer