Medical Waste Disposal Systems

Processing Regulated Medical Waste Equipment Management Information

Systems and Applications

The Mark-Costello Co. Sterilizers use the basic principle of high temperature steam under pressure in an enclosed fully automatic steam retort. The sterilizer comes completely assembled and ready for simple final connections. All chamber vessels are built in accordance with requirements of the ASME Pressure Vessel Code. All Mark-Costello Co Sterilizers are equipped with multiple safety features necessary when operating pressure vessels. The entire control panel for the standard sterilizer is Underwriters’ Laboratories listed and labeled.

All systems can be manufactured to utilize a variety of loading procedures including carts, pullout drawers or carriages. Our staff works closely with our customers to design a waste treatment system best suited for their specific needs and wants.

All standard sterilizers have the same minimal utility requirements.

All systems employ state-of-the-art technology in controls, information processing, and material handling devices to provide effortless and safe processing of bio hazardous waste.

Please contact Mark-Costello Co. today.

View our Medical Waste Sterilizer brochures

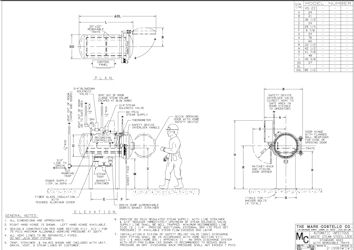

Medical Waste Sterilizer System Drawings in PDF

Standard Medical Waste Sterilizer System

The standard high-pressure steam gravity-type sterilization units are simple to operate and inexpensive to maintain. The sterilizer has been developed for:

- Medical facilities of any size

- International airport catering services

- Pharmaceutical companies and laboratories

The medical waste sterilizer system operates using lightweight aluminum or stainless steel autoclavable carts fitted with steam resistant casters. A pullout drawer may be utilized in place of carts when feasible. The autoclavable carts must be draped with a polypropylene liner prior to filling unless independent autoclavable bags have been previously filled with red bag waste.

Once the autoclavable carts are filled they are moved into the sterilizer chamber via a ramp or scissor lift. The sterilizer door is secured and with a push of the button the cycle begins. Once the desired time and temperature parameters have been met, the unit automatically shuts down and returns to ambient pressure. The carts are removed and the treated waste is ready for final disposal.

All standard sterilizers are factory-set to begin the cycle when the internal temperature reaches 275° F. continuing for a 60-minute cycle. Higher temperatures and shorter cycle times can be set by the customer when desired. If there is an interruption in the cycle for any reason, the sterilizer will automatically restart the timer.

High Volume Waste Sterilization System

The High Volume waste sterilization system functions similarly to the Standard System in that they are gravity-type, high temperature steam operated and require the same time and temperature specifications.

Larger systems are utilized primarily by Waste Processing Centers of large Medical Facilities. The sterilizers are specialty designed to cope with the fast-paced action normally encountered in a waste processing plant. They have substantially larger piping and valves. The larger chambers have dual piping and dual valving. The optional double door feature allows for efficient material flow through the sterilizer. Load doors feature hydraulically operated locking/unlocking rings. Autoclavable carts are double the size of the standard unit carts and may be trainable.

There are currently Mark-Costello Co. High Volume Waste Treatment Systems in operation processing up to 3,000 pounds per hour, 24 hours per day.

High Vacuum Type Sterilizers

High Vacuum Type Sterilizers, in all sizes, are available upon request.

Semi-Automatic Waste Sterilization System

This unit has been designed to further reduce handling of untreated biohazardous waste when using cart-loaded sterilizers. It includes lidded, lockable autoclavable carts. Carts are filled at the point of generation, taken to the treatment area and loaded directly into the sterilizer chamber eliminating the need to transfer the waste from hospital waste container to the autoclavable cart. Once the cycle is finished and the waste cart dumped, these same carts can be taken back to their original location to be refilled.

Totally Automated Robotic System

The fully equipped system will include an optional waste grinder, compactor, cart dumper, PLC controls and remote monitoring along with robotic arms, a robotically operated waste carriage and a sterilizer. Bar-coding of carts is also available.

Waste receptacles that are placed at the points of generation can be bar-coded again when they are brought to the processing area. The carts are then weighed and dumped into the sterilizer chamber carriage via a hydraulically operated cart dumper. Once the carriage is full, it is automatically moved into the sterilizer chamber. The chamber door is hydraulically closed and secured. Once the treatment cycle is complete, the load door automatically opens and the carriage robotically pulled out and dumped, either onside or over, into a grinder or compactor. The entire process is PLC Controlled and can be remotely monitored, including troubleshooting, anywhere in the world. At no time during the entire process does the operator come into contact with the waste.

Whatever your medical waste or hazardous waste disposal requirements might be, the Mark-Costello company has a solution for you. For more information and immediate assistance with your waste sterilization and disposal needs, please contact Mark-Costello Co. today.