Mark-Costello’s Space Saving Side-Eject Horizontal Balers

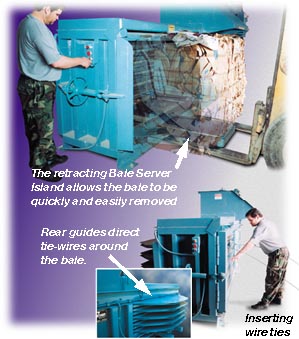

Mark-Costello’s *patented line of Side-Eject Horizontal Balers are uniquely engineered to maximize productivity. The Side-Eject saves valuable space with the bale access and tie-off system in the front of the unit. Another unique feature of the Side-Eject is the serving island that ejects the bale and puts it in a position for the fort lift to remove the bale. The Side-Eject Balers have many features not found on conventional closed-end balers.

The Side-Eject Balers are ideal for baling a variety of recyclable materials such as aluminum cans, PET, OCC, paper, etc.

*U.S. Patent No. 5,247,880

Features and Benefits

- Switch recyclables without contamination and maximize the value of your product.

- Minimize spillage between bales and reduce the need to “double handle” materials.

- Remove finished bales quickly and automatically with the unique Serving Island that extends to eject the bale and position it for pick-up by a forklift or pallet jack to help improve efficiency of your operation.

- Exclusive Front Bale Tie-Off System saves valuable floor space and eliminates trips behind the baler.

- Advanced Self-Contained Power Unit with all valves contained in a single manifold to minimize the number of hose connections.

- Bolt-On Shear Blades are adjustable and replaceable.

- Spring-Loaded Retainer Dogs located on each side of the bale chamber to produce superior springback control of recyclable materials.

- Hydraulic Door Latch standard (on all models except the 620-E)

- Programmable Controller customizes operation and eliminates relays and timers that can cause maintenance problems. Each electrical component is UL and CSA listed.

Mark-Costello’s Patented Automatic Side Ejection Features Push Button Ease

Here’s How It Works…

Pressure is relieved from the bale in three directions to achieve positive and complete bale ejection from the chamber.

This advanced method of bale ejection begins by activating the “Home Button” which causes the platen to retract to a pre-set location relieving end force on the bale. The operator then opens the chamber door which relieves side force and automatically unlocks the hinged upper section of the chamber to relieve vertical force on the bale.

With pressure on the bale effectively relieved from all directions, a hydraulic powered Server Island, located on the floor of the bale chamber, pushes the bale out of the chamber, quickly and completely. The server island functions as a pallet, eliminating costly construction of permanent guide islands. After the bale is removed with a forklift or pallet jack, the server island is retracted–saving valuable space.

Save Valuable Space

Install the Mark-Costello Side-Eject Baler up against a wall or in a tight space. Minimal floor space is needed for operation due to Mark-Costello’s unique Front baler Tie-Off and Side-Eject design.

Structural Dimensions

| A | B | C | D | E | F | G | |

| SE-504842-830 | 20′-10″ | 77″ | 105″ | 55″ | 92″ | 86″ | 97″ |

| SE-504242-830 | 20′-10″ | 71″ | 105″ | 55″ | 92″ | 86″ | 97″ |

| SE-503042-830 | 20′-10″ | 59″ | 105″ | 55″ | 92″ | 86″ | 97″ |

| SE-503042-720 | 20′-10″ | 59″ | 105″ | 55″ | 92″ | 86″ | 97″ |

| SE-503042-620-E | 20′-10″ | 59″ | 88″ | 55″ | 92″ | 86″ | 97″ |

Performance Data

| Bale Size | Bales Weight (OCC) | Cycle Time | Platen Force | Platen Pressure | Motor | Weight | |

| SE-504842-830 | 48″x42″x72″ | 1,800- 2,000 lbs. | 20 sec. | 125,700 lbs. | 63.9 psi | 30 hp | 18,700 lbs. |

| SE-504242-830 | 42″x42″x72″ | 1,600- 1,800 lbs. | 20 sec. | 125,700 lbs. | 73.0 psi | 30 hp | 17,700 lbs. |

| SE-503042-830 | 30″x42″x72″ | 1,300- 1,500 lbs. | 20 sec. | 125,700 lbs. | 102.2 psi | 30 hp | 15,200 lbs. |

| SE-503042-720 | 30″x42″x72″ | 1,200- 1,400 lbs. | 22 sec. | 96,200 lbs. | 78.2 psi | 20 hp | 15,000 lbs |

| SE-503042-620-E | 30″x42″x72″ | 1,100- 1,300 lbs. | 41 sec. | 70,700 lbs. | 57.5 psi | 20 hp | 12,400 lbs. |